Torque is a fundamental concept in mechanical systems, representing the rotational force that drives machinery, vehicles, and equipment. In practical terms, higher torque allows machines to move heavier loads, overcome resistance, and perform demanding tasks with efficiency. Achieving higher torque is especially critical in heavy-duty applications, industrial machinery, and automotive systems where power must be transmitted reliably and consistently.

One of the most effective ways to increase torque is through careful gear selection and configuration. The type of gears, their size, material, and arrangement directly influence how much torque can be delivered to the load. By optimizing gear ratios, using appropriate high-strength materials, and designing systems for efficient power transfer, engineers can enhance torque output while maintaining system reliability and durability. Understanding these principles is essential for anyone looking to maximize the performance of a high torque gearbox.

Understanding Torque Multiplication in Gears

Torque multiplication is a core principle in mechanical power transmission, allowing systems to deliver greater rotational force to a load without increasing input power. In its simplest form, torque increases when a smaller driving gear engages a larger driven gear, transferring force over a greater radius. This fundamental concept underlies the design of high torque gearboxes across automotive, industrial, and heavy machinery applications.

1. Gear Ratio and Torque Amplification

The gear ratio—the ratio of the number of teeth on the driven gear to the driving gear—directly determines the level of torque amplification. A higher gear ratio results in greater torque output at the expense of rotational speed. For example, in a first gear of a car or a reduction stage in a gearbox, torque is maximized to overcome initial load resistance.

2. Balancing Torque and Rotational Speed

While higher torque is desirable for moving heavy loads, it comes with a reduction in speed. Engineers must carefully balance torque multiplication with the system’s rotational speed requirements to ensure smooth operation and prevent mechanical stress.

3. System Efficiency and Load Capacity

Effective torque multiplication also depends on the gearbox’s ability to handle the amplified forces. Proper material selection, tooth design, lubrication, and bearing capacity are essential to prevent wear, heat buildup, and premature failure. By aligning torque multiplication strategies with system design, a high torque gearbox can achieve optimal performance, reliability, and longevity.

Choosing the Right Gear Types for High Torque

Selecting the right gear type is key to achieving higher torque efficiently. Different gears handle varying loads, speeds, and applications:

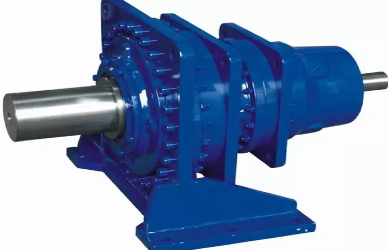

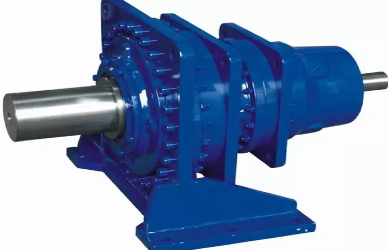

1.Planetary Gears

Compact design with multiple contact points allows significant torque multiplication, ideal for robotics, heavy machinery, and automotive applications.

2.Worm Gears

Provide very high torque at low speeds, suitable for lifting systems, conveyors, and heavy-load applications, though less efficient due to sliding contact.

3.Helical Gears

Angled teeth enable smoother engagement, higher torque capacity, and quieter operation, perfect for continuous heavy-duty industrial use.

4.Spur Gears

Simple, cost-effective gears for moderate torque applications, commonly used in standard industrial machinery.

5.Matching Gear Type to Application

Planetary for compact high-load setups, worm for low-speed high torque, helical for smooth continuous load, spur for simple moderate torque. Correct selection maximizes torque, reduces wear, and prolongs gearbox life.

Optimizing Gear Ratios

Optimizing gear ratios is a critical strategy for achieving higher torque in high torque gearbox systems. Careful selection of ratios ensures that torque is amplified efficiently, without compromising reliability, safety, or the lifespan of the gearbox.

1.Increasing Reduction Ratios

Using a smaller driving gear to turn a larger driven gear creates a mechanical advantage, multiplying torque output. This principle allows heavy loads to be moved or lifted with less input force, making it ideal for applications such as cranes, conveyors, and heavy-duty machinery.

2.Multi-Stage Gear Systems

For applications that require extreme torque, multi-stage gearboxes divide the load across multiple gear stages. Each stage progressively increases torque, reducing the stress on individual gears and preventing premature wear. This approach also maintains smooth and controlled motion even under heavy loads.

3.Balancing Torque, Speed, and Efficiency

While higher torque is desirable, it often comes at the cost of reduced output speed. Designers must carefully balance torque amplification with required rotational speed and overall system efficiency. Properly optimized gear ratios ensure that high torque gearboxes deliver maximum force while maintaining energy efficiency and operational stability, making them suitable for industrial, automotive, and specialized heavy-duty applications.

Material and Design Considerations

When designing a high torque gearbox, material selection and component design are critical to ensure reliable performance under heavy loads. Proper engineering minimizes wear, prevents failure, and extends service life.

1.High-Strength Materials and Heat Treatment

High torque gearboxes often use alloy steels, hardened metals, or advanced composites capable of withstanding extreme forces. Heat treatment processes such as carburizing, nitriding, or induction hardening increase surface hardness, enhance wear resistance, and improve overall durability. These measures ensure that gears can handle repeated high-torque cycles without deformation or failure.

2.Tooth Geometry Optimization

The shape and profile of gear teeth play a vital role in torque transmission. Optimized tooth geometry increases the contact area between meshing gears, distributes forces evenly, and reduces stress concentration points. This reduces the risk of pitting, tooth breakage, and uneven wear, which is essential for maintaining consistent high-torque output.

3.Shaft and Bearing Design

Shafts and bearings must be engineered to accommodate higher torque loads. Larger, precision-engineered shafts resist bending and twisting under load, while high-capacity bearings absorb radial and axial forces effectively. Properly designed shafts and bearings reduce friction, enhance stability, and ensure smooth operation, even under extreme torque conditions.

By integrating high-quality materials, precise tooth design, and robust shaft and bearing systems, high torque gearboxes can deliver maximum performance while maintaining durability and reliability across demanding applications.

Advanced Techniques to Increase Torque

For applications demanding extreme torque, engineers can implement several advanced techniques to enhance gearbox performance and reliability.

1.Combining Multiple Gears in Series

Using a series of gears in multi-stage configurations allows torque to be multiplied progressively across each stage. This approach enables high torque output without overloading a single gear, distributing the load more evenly and reducing wear on individual components. Multi-stage setups are especially effective in heavy machinery, conveyors, and industrial automation systems.

2.Compound Planetary Systems and Cycloidal Gearboxes

Compound planetary gear systems and cycloidal gearboxes are designed for maximum torque density. Planetary systems distribute torque across multiple planet gears, allowing compact designs to deliver high load capacity. Cycloidal gearboxes, with their rolling contact and eccentric motion, provide exceptional shock-load resistance and smooth torque transmission, making them ideal for robotics, cranes, and precision heavy-duty applications.

3.Proper Lubrication and Thermal Management

High torque operations generate significant heat, which can degrade gear materials and reduce efficiency. Using specialized lubricants with high load-bearing capacity and implementing thermal management techniques, such as heat sinks or forced cooling, prevents overheating and minimizes wear. This ensures the gearbox operates reliably under continuous high-torque conditions.

By combining multi-stage gear arrangements, specialized gearbox designs, and effective lubrication and cooling, engineers can achieve maximum torque output while maintaining durability, efficiency, and long-term performance.

Conclusion

Achieving higher torque in mechanical systems requires a combination of strategies, including selecting the appropriate gear type, optimizing gear ratios, and using high-strength materials with advanced design features. Proper consideration of these factors ensures that high torque gearboxes can handle demanding loads efficiently and reliably.

For businesses and engineers seeking tailored solutions, partnering with experienced manufacturers like Zhejiang Baffero Driving Equipment Co., Ltd. is essential. Their expertise in designing and producing high torque gearboxes ensures safe, efficient, and long-lasting performance for industrial, automotive, and heavy-duty applications.